Medina site training workers in Buffalo and Rochester for critical manufacturing skills

CNC Technical Solutions has partnerships with GCC, ECC and Autoworkers

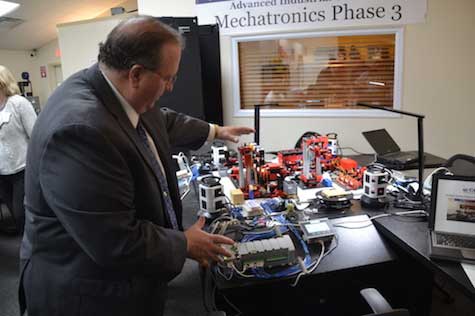

John Nappa, CEO and founder of CNC Technical Solutions, shows a four-station work site the company just patented that trains people in mechatronics.

MEDINA – John Nappa says the time is right for people to work in manufacturing. He said businesses are investing in plants with new technology. They just need employees to run the machines, and trouble-shoot and repair them.

Nappa started his career as a controls technician for Gleason Works in Rochester and then worked as an electrical engineer for American Axle in Buffalo.

He saw manufacturing evolving with “high technology exploding.” However, companies struggled to train employees.

“We have a national skills gap,” Nappa said during a graduation ceremony on Monday, where 35 people earned certifications. “The plants have been saying they need more technical people to run and repair equipment.”

Ten years ago he started the CNC Technical Solutions Training Center at his then home in Lyndonville. He moved the business to Medina nine years ago in a building that was a former church.

He has invested in the property, as well as a former warehouse next door, cleaning up a blighted area on the east side of the village.

Nappa likes the location in Medina in between Rochester and Buffalo. He also has room to grow.

He was praised by leaders of Genesee Community College, Erie Community College, and the United Auto Workers during a graduation program on Monday at CNC.

Joshua Nearhood of Creative Food Ingredients is congratulated for completing the Phase 1 course in mechatronics taught at CNC Technical Solutions in Medina.

Nappa and his company of 20 employees train people in “mechatronics” – a combination of mechanical knowhow and electronics.

Very reputable companies in Western New York are sending employees to CNC in Medina, where they attend eight-hour classes once a week over 17 weeks. The graduates on Monday included workers from Ford Motor Company, United Steelworkers, Perry’s Ice Cream, Derrick Corporation, Rosina Food Products, Liberty Pumps, Bouduelle USA, Chassix Automotive, and several others, including nearby Brunner in Medina.

Nappa and his team have created a course where students have to practice the theories they are learning in the textbook. CNC on Friday filed a patent for a four-station mechatronics factory simulation system. Nappa is being wooed by other areas to run similar training programs.

“We are blown away by the quality of education here,” said Dr. Kathleen Schiefen, provost and executive vice president of academic affairs for GCC.

The college is signing an agreement with CNC where students can use the class towards college credits.

“They are training the manufacturing technicians of tomorrow,” she said. “It’s a magnificent way to do education.”

Kelly Kiebala, director of the Job Development Agency in Orleans County, welcomes graduates and officials to the ceremony on Monday CNC Technical Solutions. Job Development also is partnering with CNC for job training services.

Erie Community College also praising Nappa and CNC. ECC has referred 75 students to CNC since 2013, said Dr. Richard Washousky, the provost and executive VP for academic affairs at ECC.

“We’ve been receiving great feedback from all of the companies,” Washousky said about the program at CNC.

The community college leaders also commended the state for providing Workforce Development funding for the program.

State Sen. Rob Ortt, R-North Tonawanda, said the state should be investing in workforce training, especially for the manufacturing sector.

“These kinds of programs are so important to the future of our state and country,” Ortt said.

State Sen. Rob Ortt said businesses need more skilled technicians and labor for manufacturing to thrive in the state and country.

The state needs more businesses that “make things,” Ortt said. And those companies need employees with the right skill set.

Nappa said the vocational trades are in demand, and those workers can often start right out of high school and good-paying jobs without the burden of crushing student debt.

“Millions of good jobs exist for people willing to learn technical skills,” Nappa said.

Joseph Tomlinson, the apprenticeship coordinator for the UAW at Ford Motor Company, said the Ford employees trained by CNC do very well on the tests at Ford in Detroit.

He said the CNC system has employees mastering core competencies, even in electronics and mechanics aren’t in their background.

He said CNC has an important role in the region’s and country’s future by training people to excel in manufacturing.

“This country – the only way it will survive – is to start building things again,” Tomlinson said.

Joseph Tomlinson, the apprenticeship coordinator for the UAW at Ford Motor Company, said companies are putting more resources into training employees to run manufacturing sites that are becoming increasingly high-tech.