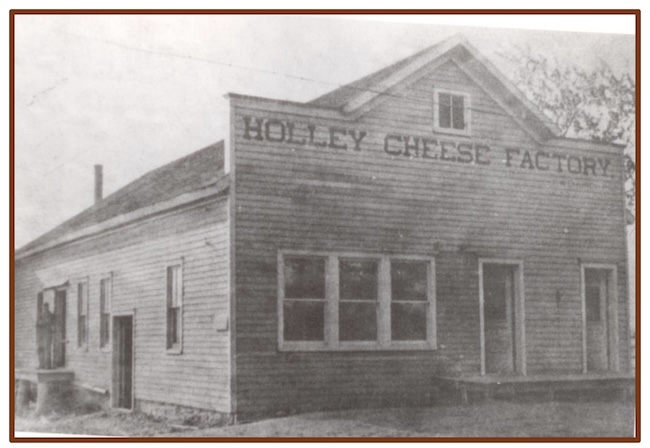

Holley, Clarendon were once home to popular cheese factories

By Catherine Cooper, Orleans County Historian

“Illuminating Orleans” – Volume 4, Number 28

How many cows will be needed to supply milk for a cheese factory manufacturing 1,000 pounds of cheese daily?

Though Central New York emerged as the center of cheesemaking in New York state, two small facilities in eastern Orleans manufactured popular cheese in the early 1900s.

In a 1952 article, Ray Tuttle, a columnist with the Holley Standard, traced the cheese-making tradition in Holley back to the descendants of immigrants from Somerset County in southeast England, the “home” of cheddar cheese. George Tuttle, Ray’s grandfather, was one such descendant. Ray wrote that his grandfather, George, made the first local cheddar at his farm on Telegraph Road, north of Holley. About 1897, George began making cheese in Clarendon, on the Fourth Section Road.

The Holley Cheese Factory was established in 1892. Elmer Tuttle, Ray’s father was a cheesemaker there, as was F.W. “Fred” Church who was also the general manager. The facility, which also produced butter, quickly doubled its output but could not keep pace with the demand.

In 1905, the factory produced 114,289 pounds of cheese which sold for an average of 12.03 cents per pound, for a total of $13,757.17.

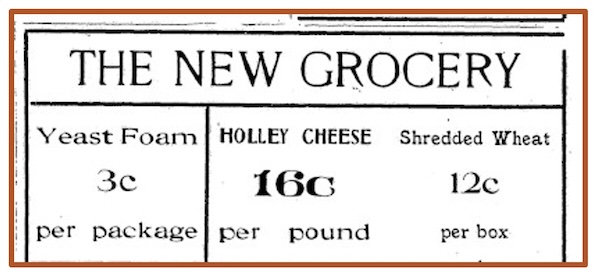

Ad in the Brockport Republican, May 1906

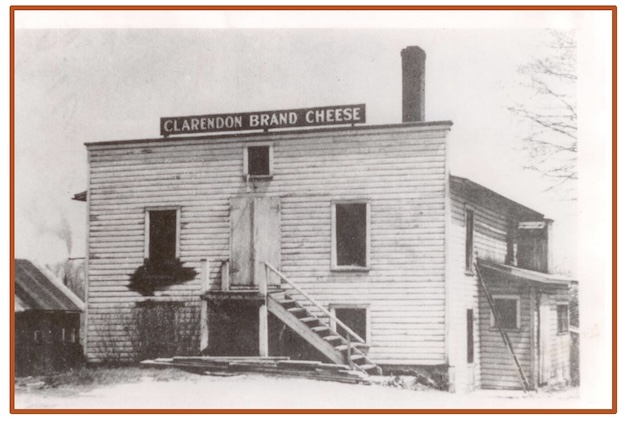

George H. “Herb” Keople, a Cattaraugus County cheesemaker, was appointed manager of the Holley Cheese Company in 1912. Three years later he built the Clarendon Brand Cheese factory on Hulberton Road.

The Holley plant closed – a newspaper article in 1917 mentioned that seven guardsmen from Tonawanda were headquartered at the “old Holley Cheese Factory.” Their duty was to guard the canal embankment between the two bridges at Holley.

This cheese factory was located on Hulberton Road in Clarendon.

During peak season – May and June – the Clarendon facility produced 1,000 pounds of cheddar cheese daily. Driving a Chevy truck, Herb Keople picked up milk from the local small dairy farmers. He would make about thirty stops, in the Clarendon and Barre areas. He employed several cheesemakers at the plant: brothers Tracy and Eddie Smith and Alfred Davis.

Only whole milk was used and at that time it would have been unpasteurized. Once produced, the cheese was placed on curing shelves – three weeks for a new cheese and up to six months for cheese with a stronger flavor. It was sold in wooden boxes which contained 35 lbs. of cheese. Clarendon cheese was very popular and was shipped throughout the country. By all accounts, it had a distinctive “tang” or “zest” which was attributed to the limestone prevalent in the Clarendon water. Milk is 87% water.

Celebrating the factory’s 25th anniversary in 1940, Mr. Keople noted that Clarendon Brand Cheese was one of the few remaining independently operated cheese factories in New York State. However, it could not compete with market forces. Larger cheese manufacturers offered to pay the farmer more per gallon, so Clarendon Brand Cheese lost its raw material and closed in 1944.

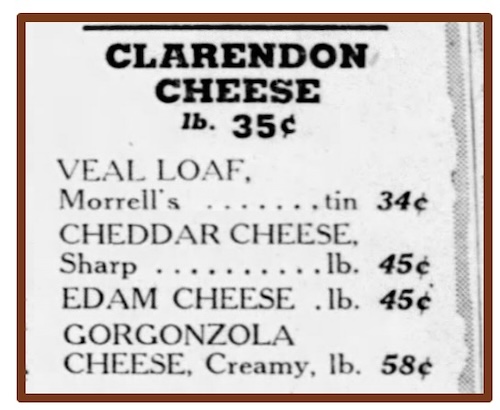

Democrat & Chronicle advertisement, 1943.

Answer to question at top: The milk yield from 180 cows would be needed to produce 1,000 pounds of cheese.