Historic Childs: Print shop took lots of time and skill

Photo by Bruce and Associates: Skilled artisan David Damico demonstrates his skill on a late 19th century mechanical printing press at the Cobblestone Museum.

(Editor’s Note: This is the tenth article in a series about historic Childs in the Town of Gaines. The hamlet of Childs lies just north of Albion at the intersection of Routes 104 and 98. In 2019, Childs was selected to be on the Landmark Society of Western New York’s “Five to Revive” list. In 1993, the federal U.S. Department of the Interior declared the Cobblestone Museum in Childs a National Historic Landmark, the first site in Orleans County with that distinction.)

By Fred Dean, Cobblestone Museum Docent

GAINES – Let’s go back in time over a hundred years ago! What would you do if you needed to print a flyer for an upcoming event or business cards for your networking needs?

Would you open up Google Docs or Microsoft Word? What if you found that you needed a program for your music performance? Today, you tap your fingers and with a quick highlight for an edit you’ll find that you’re in business.

Yes, seems pretty simple, but you will still need to pick out a font. If you had to do this a hundred years ago, this process would take a day, or two, depending on how many people were helping you, not to mention you would need a printing press and the knowhow to put your program together.

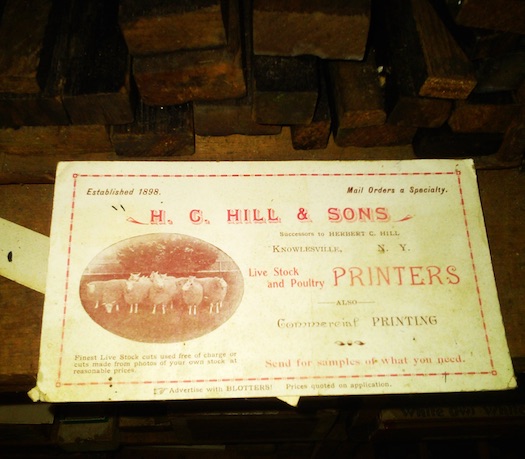

This is where a printer came in. You would need a printer that would be right for the job, such as Herbert C. Hill of Knowlesville.

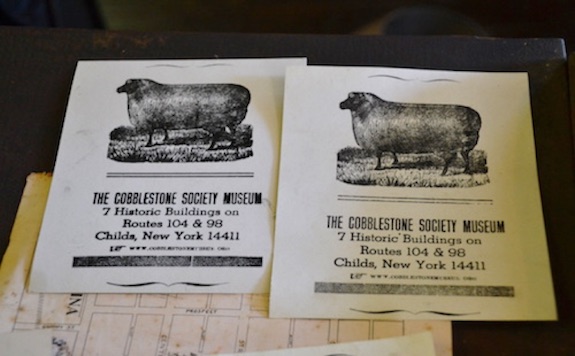

The equipment from Hill’s Print Shop is now part of the Cobblestone Museum in Childs. Hill was known as a “Job Printer” which meant he would print small jobs like invitations and letterhead for individual customers. These customers would come back and pick up their own orders. A “book printer” would work on larger orders like books and magazines. Those orders were usually shipped to the customers in another city.

Hill and other printers would take moveable type and form it to create the document you want to print. He would go to his typesetter who would pick out a font for you to use. As your new ideas came together, you would need to pick out a letter and stamp. To ensure proper punctuation you would need to get capital letters from the literal “upper case” and small letters from the “lower case.”

The need to cut the printing paper down to size by “cutting to the chase” lends us a phrase that has had its original meaning changed. It helped indicate the job of working with the chase (metal or wood frame to hold the type) to select the right type to make up the information you were printing. This process would help you know what paper you needed.

Once your order was in place, you could arrange to pick it up by telephone, another “modern” piece of technology used in the 1900s print shop. This “Bell Telephone” shown is typical of the late 1800s models. The bell in this case is clearly visible at the top of the phone, but also indicates a technology patented and perfected by Alexander Graham Bell.

Another phrase we borrow from printing today during more challenging moments takes place when we find ourselves “out of sorts.” When the printer was using fewer pieces of type due to higher costs, they may run out of lesser-used letters such as z’s and q’s during the middle of a job.

Another phrase we use today is “mind your ‘p’s’ and q’s” because the two letters were hard to distinguish when viewed in mirror-image used on typeset.

The print shop is still in working order at the museum.